Recycling plastic extruder melt pump

In today's era of resource scarcity and growing environmental awareness, the recycling of waste materials has become a focus of attention. As an important industrial equipment, recycling plastic extruder melt pump has also become a hot spot of people's attention. In this paper, we will discuss the characteristics of recycling plastic extruder melt pump, application areas and future development trends.

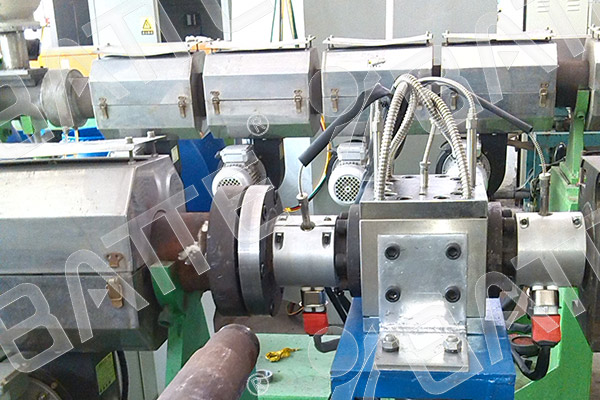

plastic extruder melt pump

First, the characteristics of recycling plastic extrusion pump melt gear pumps for plastic extruder

Recycled plastic extruder melt pump is a mechanical device specially used for conveying high temperature, high pressure, high viscosity melt, which is mainly composed of pump casing, active shaft, passive shaft, drive gears, slide bearings and other components. Compared with other ordinary pumps, recycled plastic extruder melt pump has the following characteristics:

thermoplastic melt pump manufacturer

1. strong adaptability: it can convey all kinds of high temperature, high pressure and high viscosity melts, such as polyethylene, polypropylene, polyvinyl chloride and other plastic melts.

2. high conveying efficiency: due to the use of gear drive, the pump speed is high, the flow rate is large, and the conveying distance is far, which can effectively improve the conveying efficiency.

3. High reliability: Supported by sliding bearings, the pump is able to withstand high temperature, high pressure and high viscosity melt impact, high reliability.

4. Convenient maintenance: adopting modular design, simple structure, easy disassembly and installation, low maintenance cost.

high pressure melt pump

Second, recycling plastic extruder high pressure melt pump application areas

As an important industrial equipment, recycling plastic extruder melt pump is widely used in various fields. The following are its main application areas:

1. Plastic processing industry: In the plastic processing industry, the recycled plastic extrusion melt pump is widely used in the production process of plastic products, such as plastic pipes, plastic film, plastic sheets and so on. Through the use of recycled plastic extruder melt pump, it can improve production efficiency and reduce production costs.

2. Chemical industry: In the chemical industry, recycled plastic extruder melt pumps are used to transport a variety of high-temperature, high-pressure, high-viscosity chemicals, such as polyethylene, polypropylene, polyvinyl chloride and other plastic melts. Through the use of recycled plastic extruder melt pumps, it can improve conveying efficiency and reduce labor intensity.

3. Food industry: In the food industry, melt pumps for plastic extruder are used to convey a variety of food materials, such as chocolate, fudge, jelly and so on. Through the use of recycled plastic extruder melt pump, it can improve the production efficiency and ensure the quality and hygiene of food.

extrusion melt pump

In short, as an important industrial equipment, recycled plastic extrusion melt pump will play a more important role in the future. With the continuous progress of technology and the continuous expansion of application areas, its future development trend will become more and more obvious.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071