Application of melt pumps for thermoplastic materials in extr

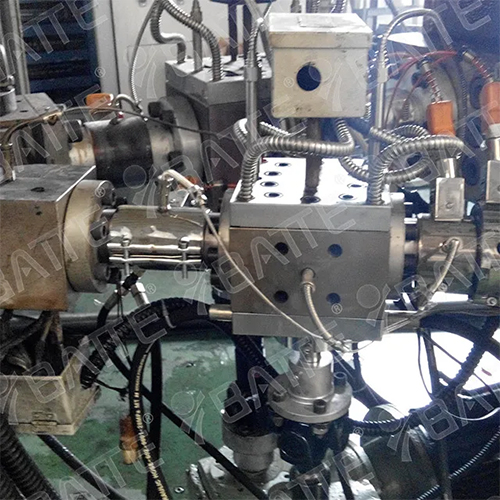

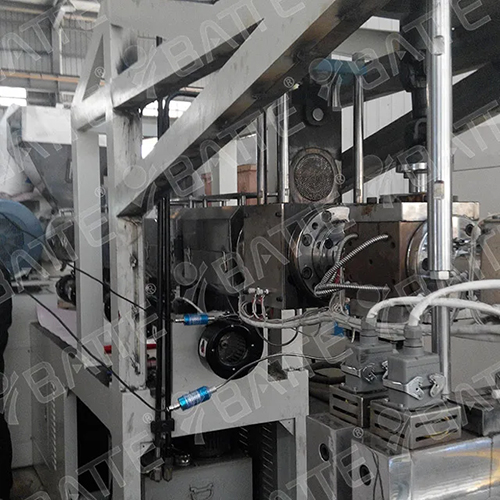

Melt gear pumps for thermoplastic materials are suitable for extrusion and transportation of thermoplastic high-viscosity polymer melts; they are generally installed between the extruder outlet and the die head as metering pumps.

Advantages of melt gear pumps for thermoplastic materials

1、Extremely small pressure and flow pulsation, can realize the linear output of flow, suitable for precision extrusion system.

2, for different working conditions using different structures and materials configuration, to better meet the user's individual needs.

3、It can be applied to high temperature (350℃), high pressure (40MPa), high viscosity (40,000Pass) working conditions.

4、Precise structure, high precision and long life.

Zhengzhou BATTE is familiar with the extrusion process of various plastics and rubber materials, and has a lot of experience in the application of melt pumps for extrusion systems, providing a complete set of melt conveying, pressurizing and metering solutions for a number of listed companies in China. Zhengzhou BATTE provides a variety of melt gear pumps for various sheet, plate, pipe, film, wire drawing, underwater pelletizing, masterbatch extrusion pelletizing, rubber pre-molding and other extrusion systems, which are widely used in a variety of polymers and macromolecule materials.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071