Characteristics of gear pumps for rubber and elastomer melt p

Rubber is a polymer material with high elasticity, which is elastic at room temperature and can undergo significant deformation under small external forces. After removing external forces, it can return to its original state. Rubber products are widely used in various aspects of industry or daily life. Elastomers can be divided into thermosetting elastomers and thermoplastic elastomers, with a wide range of materials and a wide range of applications. In response to the performance characteristics of this type of material, our company has specially developed the ZB-R series of melt gear pumps for rubber and elastomers.

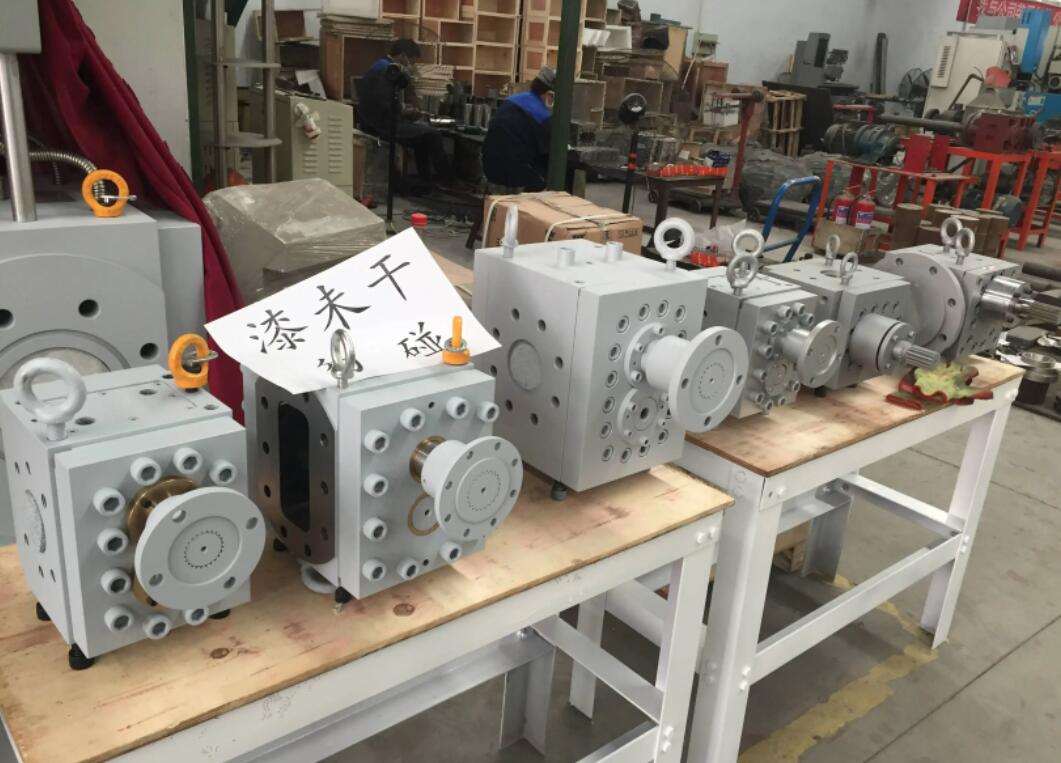

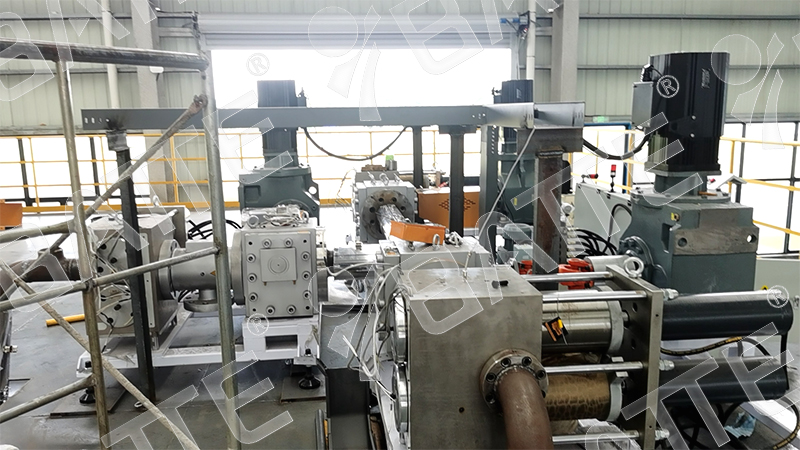

The characteristics of the ZB-R series melt gear pump: generally installed between the extruder outlet and the die head, used as a melt metering pump; The pump casing is equipped with a built-in flow channel, which can be used for cooling or heating with thermal media; Built in cooling channels for faster and more efficient temperature control; Specially designed lubrication channels suitable for rubber and elastomer materials; Optimized flow channel design with fewer dead corners; Both electric heating and thermal medium heating are applicable; Suitable for working conditions with strict temperature requirements.

The installation of a melt gear pump in the extrusion system can significantly improve the stability of the die head pressure, thereby improving the quality of the work in progress; At the same time, it can also increase extrusion volume, increase production, and save costs for users. Zhengzhou Batte provides rubber and elastomer specific melt pumps with specifications ranging from 5CC/R to 5000CC/R, which have high precision, stable flow rate, and no pulsation output. The company has many years of production and application experience, providing you with strong technical support and quality assurance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071