Precautions for assembly of melt pump head

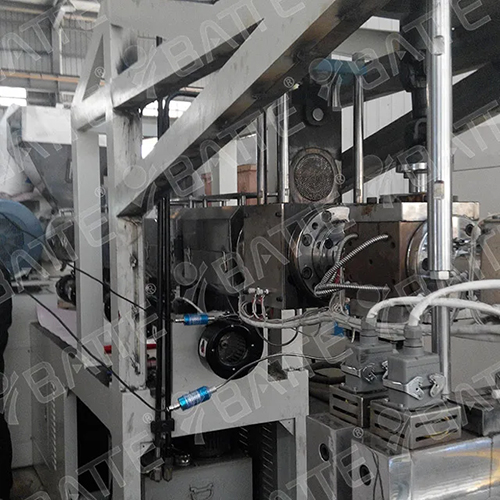

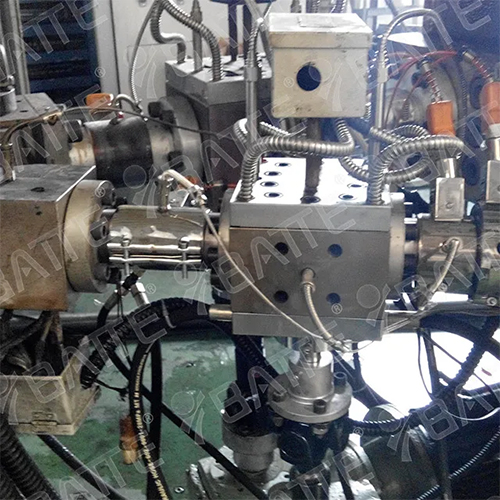

The entire sleeve type melt pump is mainly composed of four parts: motor, reducer, universal coupling, and pump head. The pump head of the melt pump is mainly composed of pump casing, front and rear covers, main and secondary gear shafts, sliding bearings, and shaft seals. The following are the specific assembly steps and precautions for the melt pump head introduced by the melt pump manufacturer.

Use trichloroethane or vinyl chloride flux to clean all pump components to be assembled (such as bearing locating keys). During the assembly process of the melt pump, it is necessary to frequently rotate the gear of the melt pump by hand to ensure that it can rotate freely. Whenever there is a jamming phenomenon during assembly, the cause must be identified and resolved before proceeding to the next step. If there are minor scratches, burrs, or external debris, it can cause damage to important components. When assembling, do not forcefully assemble or rotate the melt pump. If the transfer is correct, all parts can be easily inserted into the melt gear pump, and the rotation of the shaft is also very flexible.

During assembly, the pump body should be clamped using a soft mouthed platform.

Before installing the bolts, apply DAG154 or similar high-temperature resistant lubricating grease to the threaded area, and tighten the bolts on the end cover plate in an oblique manner. First, tighten with a recommended torque value of 1/4 of 1/2, then tighten with 3/4 of 1/2, and then tighten with full torque.

Install the sealing chamber on the shaft, do not tighten the bolts of the sealing chamber to make it slightly loose, as this will align the seal. Fix the sealing cover on the shaft, align the bolt holes of the cover plate with the bolt holes on the sealing component, fix the bolts on the sealing component, and fix the sealing cover together evenly with diagonal lines. Press the sealing component smoothly into the sealing chamber. When the cover plate fully contacts the sealing component, remove the cover plate, tighten the bolts of the sealing component, and tighten them.

Melt pumps are widely used in the extrusion molding of plastic, resin, rubber products, such as granulation, film, pipe, sheet and other industries, and can be used in series with single screw or co rotating twin screw extruders to improve the efficiency of the entire production line. BATT is a professional melt pump manufacturing enterprise in China with decades of research and development experience.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071