Which materials are processed by thermoplastic melt pumps?

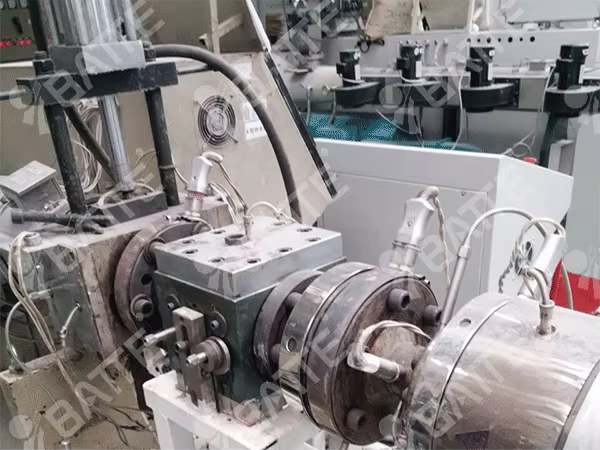

The thermoplastic extrusion pump is primarily utilized for the transportation, pressurization, and metering of high-temperature, high-viscosity polymer melts. Its application scope is extremely broad, encompassing nearly all polymeric materials. Below are some common materials processed by thermoplastic melt pumps:

Common Materials:

Polyethylene (PE): Including High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE).

Polycarbonate (PC): A robust thermoplastic resin commonly used in the manufacture of electrical parts, automotive components, etc.

Polypropylene (PP): A semi-crystalline thermoplastic plastic widely applied in packaging, automotive, electronics, and electrical appliances.

Polyvinyl Chloride (PVC): A polymer formed through the polymerization of vinyl chloride monomers under the action of peroxide, azo compounds, or light and heat, according to the free-radical polymerization mechanism. It is the homopolymer of vinyl chloride.

Polyethylene Terephthalate (PET): Primarily used for producing packaging bottles, films, sheets, etc.

Polysulfone: A high-performance thermoplastic plastic with exceptional heat resistance, oxidation resistance, radiation resistance, and electrical insulation properties.

Polyesters: Such as Polybutylene Terephthalate (PBT), which are also commonly processed by thermoplastic melt pumps.

Fluoropolymers: Like Polytetrafluoroethylene (PTFE), known for their superior chemical resistance.

Thermoplastic Elastomers (TPEs): Such as Thermoplastic Polyurethane (TPU), which combine the elasticity of rubber with the processability of plastics.

Rubber: Certain rubber materials can also be processed by thermoplastic melt pumps under specific conditions.

Application Fields:

Thermoplastic melt pumps are extensively used in the extrusion molding of plastics, resins, and rubber products, including granulation, film, tubing, sheet, plate, artificial fibers, optical fibers, medical plastic tubing, and other industries. In these fields, thermoplastic melt pumps stably transport melts, ensuring dimensional accuracy and quality of extruded products.

Operational Characteristics:

Compact Structure: Thermoplastic melt pumps are typically designed to be compact, occupying minimal space.

Reliable Operation: Due to their precise design and manufacturing processes, thermoplastic melt pumps operate with high reliability.

Low Energy Consumption: Through optimized design and efficient energy conversion mechanisms, thermoplastic melt pumps significantly reduce energy consumption.

High Volumetric Efficiency: They efficiently transport melts, minimizing waste.

Minimal Shearing Effect on Melt: This helps preserve the physical and chemical properties of the melt.

In summary, thermoplastic melt pumps hold vast application prospects and significant value in the plastic processing industry. As technology continues to advance and markets evolve, the performance and application scope of these pumps will continue to expand and improve.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071