What are the technical parameters of the melt pump of 2600 co

Regarding the technical parameters of the melt pump for the 2600 co-extrusion polypropylene sheet extrusion machine, since it may be difficult to directly obtain the specific technical parameters of the melt pump tailored for this particular model (such as the 2600 co-extrusion polypropylene sheet extrusion machine) from public sources, I will provide a general overview based on the typical technical parameter range of melt pumps and combined with the application characteristics of polypropylene sheet extrusion machines.

Generally, the technical parameters of a melt pump include specifications and models, delivery capacity, pressure range, temperature range, viscosity range, heating method, sealing method, and drive unit. For a melt pump used in the 2600 co-extrusion polypropylene sheet extrusion machine, its technical parameters may be as follows:

Specifications and Models

The specifications and models of a melt pump are usually represented by the displacement per revolution, with the unit typically being cc (cubic centimeters). For large extrusion machines such as the 2600 co-extrusion polypropylene sheet extrusion machine, the specifications of the melt pump may be relatively larger, but the specific model needs to be customized according to actual requirements.

Delivery Capacity

The delivery capacity is directly related to the specifications and models of the melt pump, meaning that the displacement per revolution determines the amount of melt it can deliver. For polypropylene sheet extrusion, the melt pump needs to be able to stably and continuously deliver molten polypropylene to meet the demands of the extrusion production line.

Pressure Range

The output pressure and suction pressure range of the melt pump are important parameters. Generally, the output pressure can reach 0-40MPa or higher, depending on the pump's specifications and materials. For polypropylene sheet extrusion, the melt pump needs to be able to withstand higher pressures to ensure the stability and uniformity of the melt during the extrusion process.

Temperature Range

The operating temperature range of the melt pump is usually wide to adapt to the processing needs of different materials. For polypropylene sheet extrusion, the operating temperature of the melt pump should be able to meet the melting temperature requirements of polypropylene, with a general operating temperature of up to ≤350°C, and a cleaning temperature that can reach even higher temperatures (such as ≤450°C).

Viscosity Range

The viscosity range of the medium that the melt pump can deliver is also one of its important parameters. The melt viscosity of polypropylene is affected by factors such as temperature and pressure, and the melt pump needs to be able to handle changes in the viscosity of polypropylene under different conditions. Generally, the viscosity of the medium that the melt pump can deliver can reach 1-40000Pa·s or higher, which is sufficient to meet the needs of polypropylene sheet extrusion.

Heating Method

The heating methods of melt pumps typically include electric heating and thermal oil heating. For melt pumps used in polypropylene sheet extrusion machines, electric heating is commonly used due to its advantages such as fast heating speed and precise temperature control.

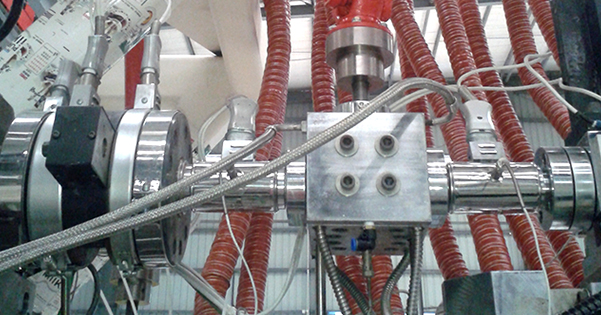

Sealing Method

The sealing method of the melt pump has a significant impact on its performance and service life. Generally, spiral sealing and packing sealing are used, with the specific choice needing to be considered based on factors such as the pump's specifications and models, working pressure, and temperature.

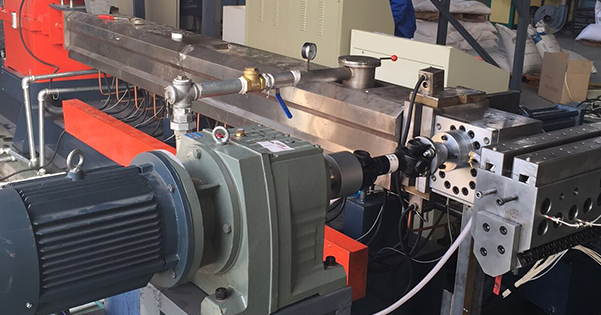

Drive Unit

Melt pumps typically adopt a drive unit consisting of an electric motor, a reducer, and a universal coupling at the pump end. This drive unit has the advantages of simple structure, high transmission efficiency, and stable operation. By adjusting the speed of the electric motor, precise control over the output flow rate of the melt pump can be achieved.

It should be noted that the above technical parameters are only general descriptions, and the specific technical parameters of the melt pump for the 2600 co-extrusion polypropylene sheet extrusion machine need to be determined based on actual requirements and the product specifications of the manufacturer. In practical applications, it is recommended to contact professional melt pump manufacturers or suppliers to obtain accurate technical parameters and customized services.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071