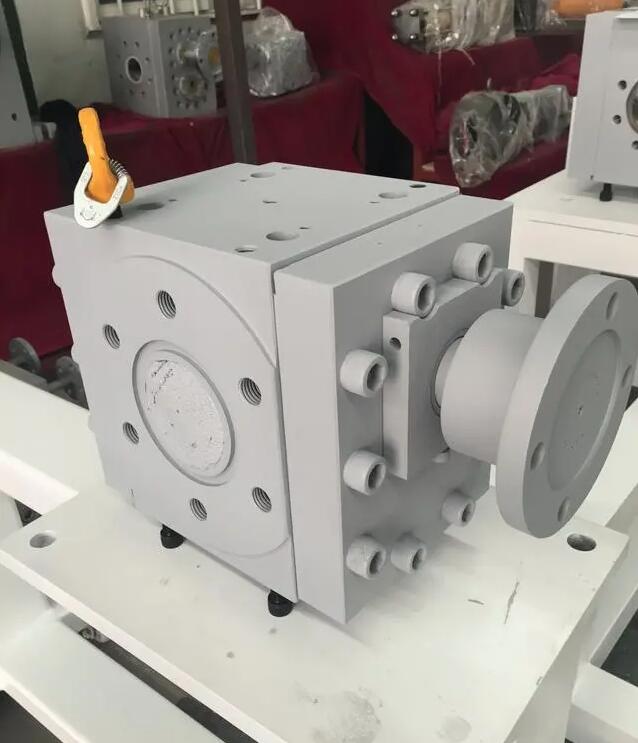

Introduction to the Structure of High Temperature Melt Pump

The structure of a high-temperature melt pump can be roughly divided into the following parts:

1. Pump casing: This is the main structure of high-temperature melt pumps, usually made of high-quality alloy steel or stainless steel to ensure stability even under high temperature and pressure.

2. Gear: This is a key part of the high-temperature melt pump, which is essential for achieving material pressurization and stable pressure transportation. Gears operate at high temperatures and are typically made of high-strength, heat-resistant alloy steel.

3. Bearings and seals: To ensure efficient operation of high-temperature melt pumps and prevent leakage, bearings and seals are crucial. These are usually made of special materials.

4. Control system: In order to ensure safe and stable operation, high-temperature melt pumps are usually equipped with a control system. This system can monitor the operating status of the pump, control flow and pressure, and has fault diagnosis function.

5. Safety protection device: In order to prevent accidents such as overload, overheating, etc., the high-temperature melt pump is also equipped with a safety protection device. These devices can detect abnormal situations and take immediate action, such as cutting off power or shutting down the pump.

The above is the basic structure of a high-temperature melt pump. Different models and applications of high-temperature melt pumps may have differences in details. If you need more detailed information or have more in-depth questions about a certain part, I would be happy to assist you.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071