What are the uses of high-temperature melt pumps?

The main applications of high-temperature melt pumps are reflected in the following aspects:

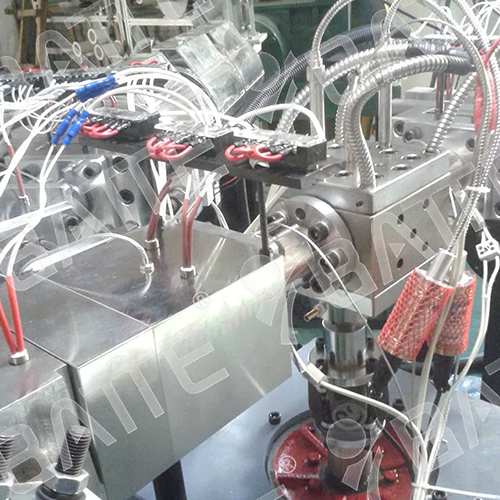

1. Transportation of high-temperature and high viscosity polymer melts: High temperature melt pumps are mainly used to transport high-temperature and high viscosity polymer melts, such as plastics, resins, rubber, etc.

2. Boosting and Stable Flow Delivery: High temperature melt pumps have the functions of boosting and stabilizing flow, especially in the extrusion molding process, which can effectively reduce material output instability and pressure pulsation caused by extruder parameters, ensuring the accuracy and stability of product dimensions.

3. Measurement function: The high-temperature melt pump can accurately measure the amount of melt transported, which is particularly important for production processes that require precise control of material usage.

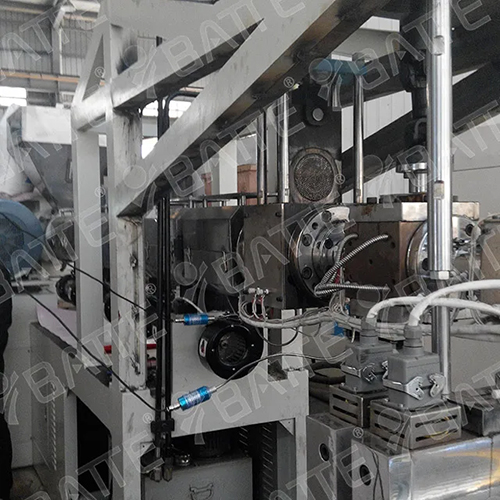

4. Application industry: High temperature melt pumps have a wide range of applications in multiple industries, including extrusion molding of plastic and resin products, such as granulation, film, pipe, sheet, and other industries. In addition, it is widely used in the production of artificial fibers, optical fibers, medical plastic catheters and other products.

High temperature melt pumps play an important role in industrial production, especially in situations that require the transportation, pressurization, metering, and stable flow of high-temperature and high viscosity polymer melts.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071