The function and characteristics of thermoplastic material ex

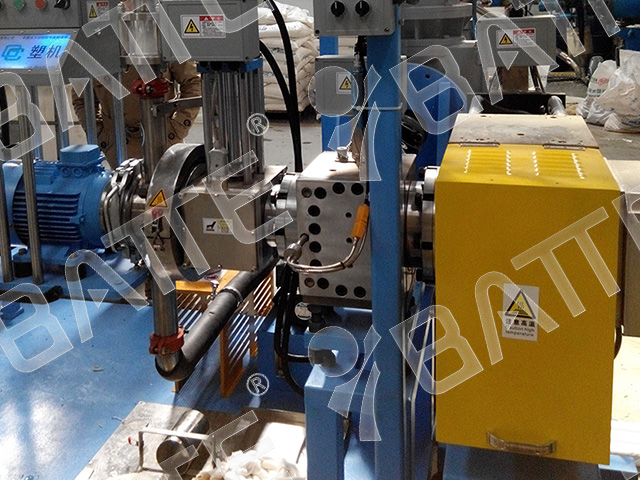

The melt pump for extruding thermoplastic materials plays a crucial role in the plastic processing industry, with its primary functions and characteristics outlined below:

Functions:

Stabilizing Die Pressure: The melt pump for extruding thermoplastic materials significantly enhances the stability of die pressure, which is vital for improving product quality.

Achieving Flow Control: The melt pump enables nearly linear output of flow, making the extrusion process more manageable and enhancing production efficiency and product consistency.

Boosting Production Capacity: By increasing the extrusion volume, the melt pump significantly raises product output, meeting the demands of large-scale production.

Reducing Energy Consumption: The melt pump reduces the load on the extruder, thereby conserving energy and lowering production costs.

Enhancing Product Quality: The use of the melt pump diminishes dimensional tolerances in extruded products, reducing scrap and waste rates, and enhancing the overall product quality.

Characteristics:

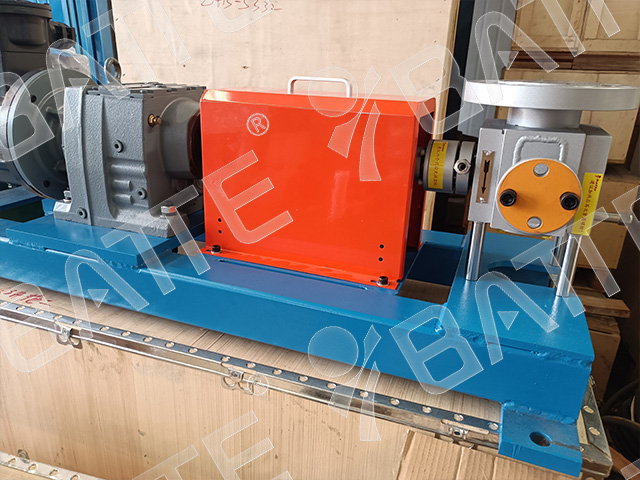

Precise Design: The melt pump for extruding thermoplastic materials boasts a precise structural design, including optimized tooth profile and dead-zone-free flow channel designs, ensuring stable and efficient material conveyance.

Strong Adaptability: This pump can be applied in high-temperature (up to 350°C), high-pressure (up to 40MPa), and high-viscosity (up to 40,000Pas) operating conditions, meeting various complex processing needs.

Multiple Installation Methods: The melt pump supports various installation methods, such as horizontal and vertical (upward or downward) arrangements, catering to different production site requirements.

Wear and Corrosion Resistance: The pump body material must be temperature-resistant, wear-resistant, and corrosion-resistant to ensure long-term stable operation in high-temperature and high-pressure environments.

Ease of Control: The output volume of the melt pump is linearly related to the gear speed, allowing precise control of melt discharge and accurate metering through speed regulation.

Energy Saving and Environmental Protection: The built-in cooling channel design enables more precise and rapid temperature control, contributing to energy conservation and reducing heat loss.

Long Service Life: Due to its high-precision manufacturing and excellent heat treatment processes, the melt pump boasts a long service life and low maintenance costs.

In conclusion, the melt pump for extruding thermoplastic materials has gained widespread application in the plastic processing industry due to its stable and reliable performance, precise control capabilities, and broad application range.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071