What are the applications of melt pumps in the plastic granul

Melt pumps have a wide range of applications in the plastic granulation industry, and the following are several of its main application aspects:

Stabilizing melt pressure and flow rate:

Melt pumps can ensure that the pressure and flow rate of the plastic melt remain stable during the conveying process. This is crucial for plastic granulation, as stable melt pressure and flow rate contribute to the production of uniform, high-quality plastic granules.

Precise metering and control:

Melt pumps possess precise metering and control functions, enabling accurate control over the conveyance volume of plastic melt. This is highly important for granulation processes that require precise control over the size and weight of plastic granules.

Enhancing production efficiency:

The use of melt pumps can significantly improve production efficiency in plastic granulation. Melt pumps can convey plastic melt continuously and stably, reducing production interruptions caused by melt pressure fluctuations, thus enhancing overall production efficiency.

Energy saving and consumption reduction:

The design of melt pumps allows them to effectively reduce energy consumption during conveyance. By precisely controlling the conveyance volume of the melt, melt pumps can avoid unnecessary energy consumption, thereby lowering production costs.

Improving plastic granule quality:

Melt pumps can ensure that the plastic melt maintains a uniform temperature and pressure during conveyance, thereby avoiding quality issues in plastic granules caused by unstable melt states. Additionally, melt pumps can reduce bubbles and impurities in the melt, further enhancing the quality of plastic granules.

Compatibility with various plastic raw materials:

Melt pumps are suitable for conveying a variety of plastic raw materials, including polyethylene, polypropylene, polyvinyl chloride, etc. This makes melt pumps widely applicable in the plastic granulation industry.

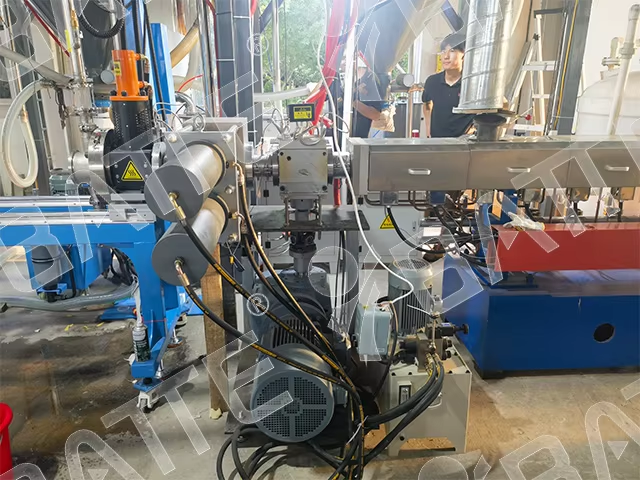

Collaborative work with granulators:

Melt pumps typically work in coordination with granulators to form a complete plastic granulation production line. The melt pump stably conveys the molten plastic raw material to the die section of the granulator, where it is cut and cooled to form plastic granules. This collaborative work mode ensures continuity and stability in the plastic granulation process.

In summary, melt pumps play a vital role in the plastic granulation industry, as they not only improve production efficiency and reduce energy consumption but also enhance the quality of plastic granules. With the continuous development of technology, the application of melt pumps in the plastic granulation industry will become increasingly widespread.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071