"Rubber Revolution: Melt Pump Takes Extrusion to the Next L

February 5, 2025 — The rubber and plastics processing industry has witnessed a significant breakthrough with the introduction of a state-of-the-art rubber extrusion melt pump. This innovative pump is designed to elevate production efficiency, ensure product quality, and reduce operational costs, making it a game-changer for manufacturers worldwide.

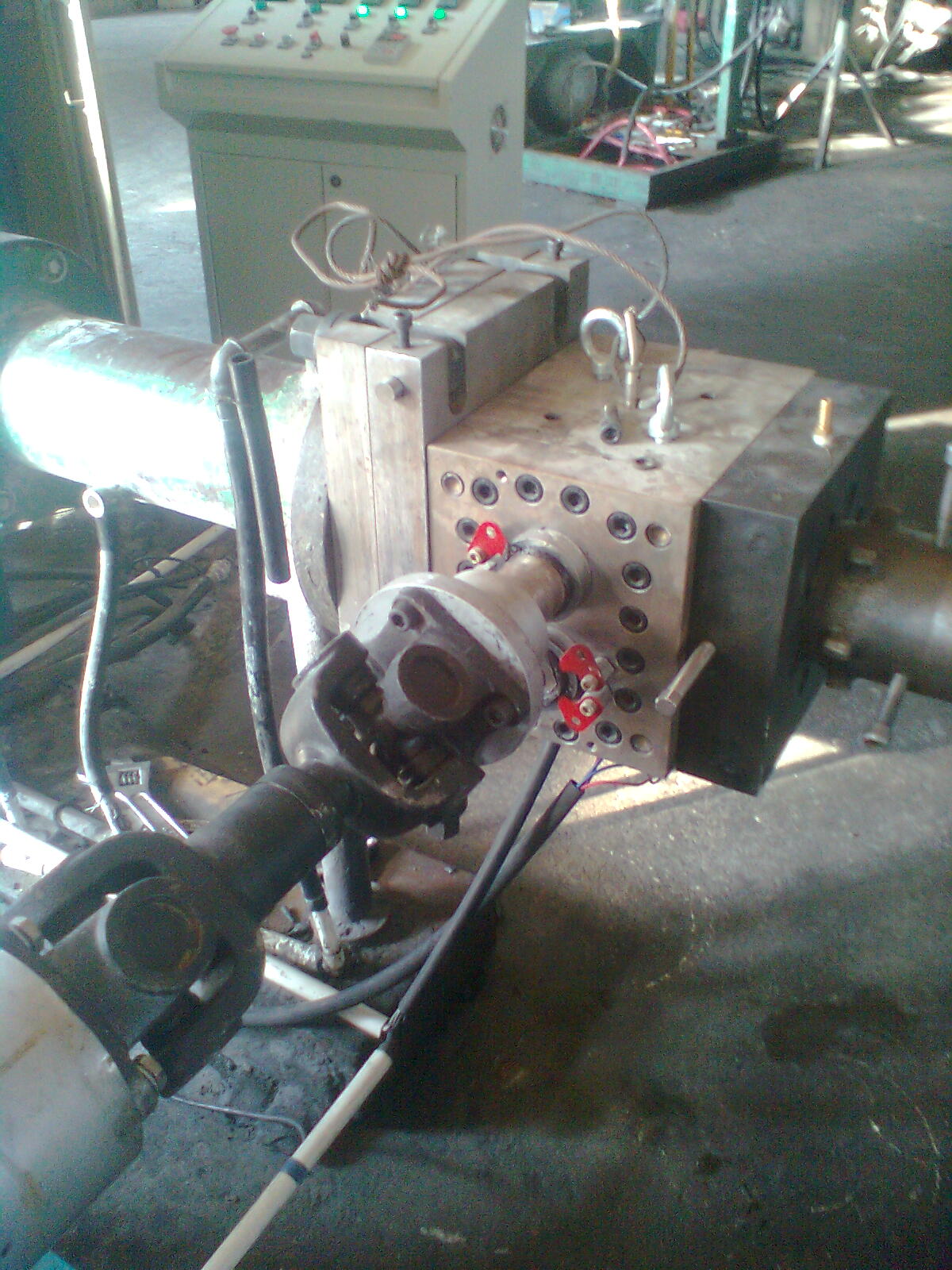

The rubber extrusion melt pump boasts a sophisticated design that combines cutting-edge technology with robust materials to meet the demanding requirements of high-temperature, high-pressure, and high-viscosity applications. Its optimized gear tooth profile ensures a smooth and stable melt conveyance, minimizing pressure fluctuations and achieving a nearly linear output flow. This precision engineering allows for better control over the extrusion process, significantly enhancing product quality and consistency.

The pump's flow channel design eliminates dead zones, drastically reducing polymer residue and improving the quality of the final product. Special lubrication and sealing structures are incorporated to handle rubber and other easily degradable materials, ensuring no material leakage and maintaining a clean operating environment. Additionally, the pump is equipped with optional wear-resistant configurations, making it suitable for high-fill applications.

A key feature of this rubber extrusion melt pump is its versatility. It can handle a wide range of thermoplastic materials, including PET, PBT, PA6, PA66, PE, PP, EVA, TPU, and various rubber and elastomer materials such as NR, BR, CR, and NBR. This broad compatibility allows manufacturers to use a single pump for multiple materials, reducing equipment costs and simplifying the production process.

The pump's structure is meticulously engineered for durability and performance. It utilizes high-strength materials like high-temperature tool steel and chromium-nickel alloy steel for the pump body and gears, ensuring long-term reliability even under harsh conditions. The pump head, the heart of the melt pump, is designed with precision-machined gears and sliding bearings that are lubricated dynamically, reducing friction and wear.

Temperature control is another critical aspect of the rubber extrusion melt pump. It employs a combination of shaft-end cooling and heat medium heating systems to maintain precise and rapid temperature regulation. This ensures that the melt remains stable throughout the extrusion process, preventing degradation or quality loss due to overheating.

Moreover, the pump's self-cleaning capability is a standout feature. The optimized flow channel and lubrication system design enable the pump to automatically clear internal residue and dead spots during operation, preventing material accumulation and clogging. This not only enhances the pump's efficiency but also extends its lifespan.

In terms of technical specifications, the rubber extrusion melt pump offers a viscosity range of 1 to 40,000 Pa•s, an inlet pressure of up to 30 MPa, an outlet pressure of up to 40 MPa, and an operating temperature of up to 350°C. These parameters make it suitable for a wide range of applications and process conditions.

Manufacturers can further customize the pump to suit their specific needs. Various installation options, multiple sealing structures, and adjustable flow rates via frequency control provide flexibility and adaptability to different production scenarios.

Industry experts have hailed this rubber extrusion melt pump as a milestone in rubber and plastics processing technology. Its ability to significantly improve production efficiency, enhance product quality, and reduce operational costs is expected to drive its adoption across various manufacturing sectors.

As manufacturers continue to seek innovative solutions to meet the growing demands of the market, the rubber extrusion melt pump stands out as a superior choice. With its combination of advanced design, robust construction, and versatile capabilities, it is poised to revolutionize the rubber and plastics processing industry.

To learn more about this revolutionary rubber extrusion melt pump and its benefits, visit [Your Company's Website] or contact [Your Company's Contact Information] for inquiries and custom solutions.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould