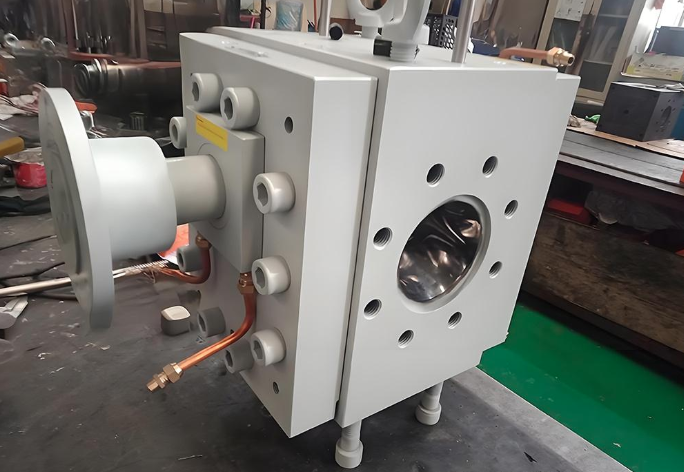

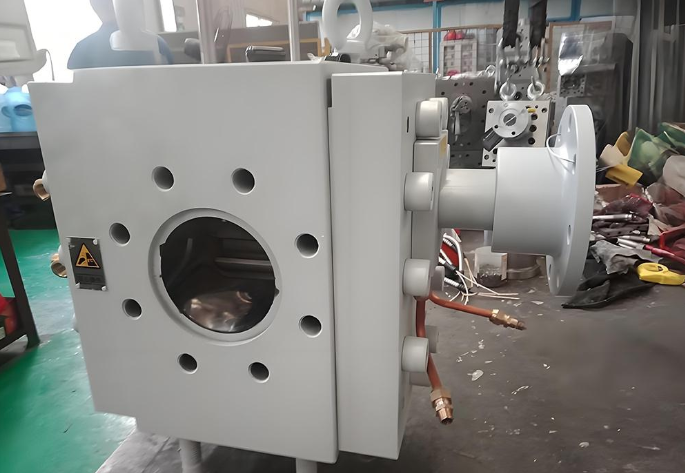

Silicone tube extrusion melt pump: multiple advantages ensure

The Silicone tube extrusion melt pump boasts multiple advantages in the production of silicone tube extrusion, which collectively ensure the stability of the production process. Below is a detailed elaboration on the advantages of the silicone tube extrusion melt pump:

Stable Output, Enhanced Product Quality

During the silicone tube extrusion process, the melt pump effectively reduces material output instability and pressure pulsation caused by variations in extruder parameters. Regardless of changes in the pump's inlet pressure, the outlet pressure and flow rate fluctuations of the pump can be controlled within a minimal range. This stability is crucial for silicone tube extrusion as it ensures that the dimensional tolerance of the extruded products is minimized, thereby improving product quality and reducing waste and scrap rates.

Increased Production, Lower Energy Consumption

The melt pump's clever design transfers the pressure reduction function of the extruder to itself, enabling the extruder to operate at lower pressures and temperatures. This not only reduces leakage flow but also significantly boosts overall production capacity. Additionally, the melt pump's efficient design allows it to more effectively establish and maintain die head pressure, reducing the extruder's back pressure and alleviating the axial force borne by the screw, thereby extending equipment lifespan and lowering unit energy consumption.

Linear Extrusion Characteristics, Facilitating Monitoring and Control

The melt pump exhibits linear extrusion characteristics, meaning that its conveying capacity is basically linearly related to its rotational speed. When the melt pump's rotational speed changes, its flow rate can be accurately determined. This characteristic enables upstream and downstream equipment to coordinate their operations, and by utilizing pressure, temperature, and other information collected at the melt pump's inlet and outlet, the entire extrusion process can be monitored and controlled online in real-time. This aids in better achieving automated control and optimization of the production process.

Versatile Applicability, Widely Used in Various Polymer Processing

The silicone tube extrusion melt pump is not only suitable for silicone tube extrusion production but can also be used for processing a variety of polymers, including various thermoplastic resins, thermoplastic elastomers, and other polymers. This broad applicability makes the melt pump play a significant role in the extrusion molding industry for plastics, resins, rubbers, and other products.

In summary, the silicone tube extrusion melt pump ensures the stability of silicone tube extrusion production through its multiple advantages, including stable output, increased production and lower energy consumption, linear extrusion characteristics, and versatile applicability. These advantages make the melt pump a valuable assistant on the silicone tube extrusion production line, providing a more stable, efficient, and energy-saving operational experience.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071