Reactor Melt Discharge Pumps: Structure, Applications and Adv

Under 350℃ high temperature and 30000Pa-s viscosity limit working condition, the reactor melt discharge pump drives the efficient production of plastics, chemical fiber and other industries with 15MPa stable pressure, the precision structure ensures the flow rate near linear output, and the self-priming performance breaks through the vacuum conveying problem, providing reliable power core for polymerization reaction and melt spinning.

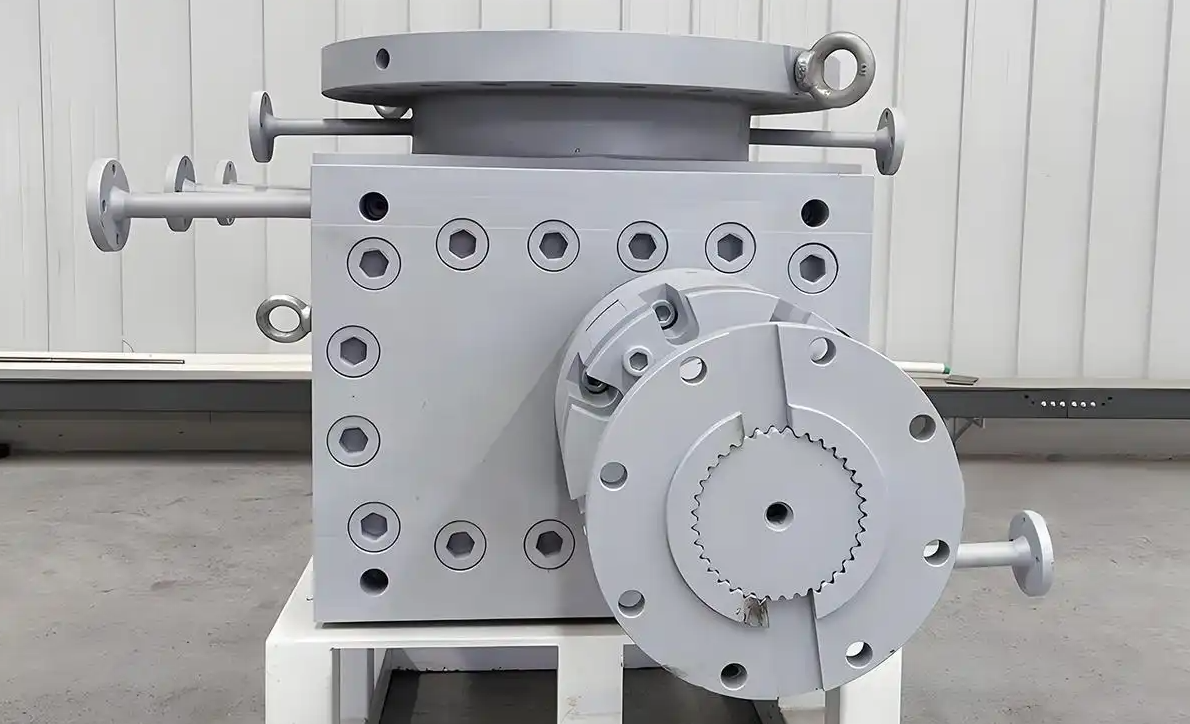

Structure of reaction kettle melt discharge pump

Reactor melt discharge pump is usually installed at the bottom of the reactor and used as a discharge pump. Its structure mainly includes pump body, front and rear side plates, two intermeshing gears, bearings and seals. The pump body is made of various materials, such as stainless steel, alloy steel, corrosion-resistant alloys, etc., in order to adapt to different media and working environment. Gear materials are also available in a variety of options, such as nitrided steel, tool steel, etc., to ensure the efficient operation of the pump. Its sealing structure includes melt dynamic seal + packing seal, high temperature resistant packing seal, etc. to ensure the safe and reliable operation of the pump.

Features of reaction kettle melt discharge pump

High-efficiency conveying: the reactor melt discharge pump has excellent output pressure and high-viscosity media handling capacity, which can efficiently and stably convey high-viscosity liquids.

High adaptability: it can be applied to high temperature (up to 350℃), medium and high pressure (up to 15MPa), high viscosity (up to 30,000Pa-s) working conditions to meet specific process requirements.

Stable flow: small pressure-flow pulsation, can realize nearly linear output of flow, easy to control.

Good self-absorption performance: it can be applied to the working condition where the inlet is vacuum, which can make the high-viscosity medium smoothly inhaled under vacuum condition and complete the transportation and pressurization of polymer materials.

Precise structure: the pump body is made of excellent material and the sealing structure is reliable, which ensures the safe and reliable operation of the pump. At the same time, it is also characterized by high precision and long life.

Wide range of parameters: wide range of viscosity of conveying medium, from low viscosity to high viscosity can be easily dealt with. Parameters such as inlet pressure, outlet pressure and operating temperature also have a wide selection range to meet the needs of different process conditions.

In short, with its unique working principle, excellent structural design and outstanding features, the reactor melt discharge pump plays an important role in chemical, plastic, rubber and other industries.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071